Construction projects are rarely straightforward. For general contractors and MEP specialists, the job site often feels like a complex puzzle where the pieces—ductwork, piping, electrical conduit, and structural beams—don’t always fit together as planned. Traditional 2D drawings often fail to reveal conflicts until installation begins, leading to costly rework, schedule delays, and eroded profit margins.

Building Information Modeling (BIM) offers a powerful solution to this chaos. However, simply having a 3D model isn’t enough. The real value lies in how effectively a contractor integrates coordination processes into their daily workflow. When done correctly, BIM moves problem-solving from the construction site to the computer screen, saving time and money.

This article outlines eight practical ways contractors can integrate MEP BIM coordination into their projects to drive efficiency and build with confidence.

8 Effective Ways to Integrate MEP BIM Coordination

Implement Coordination Before Breaking Ground

The most effective way to integrate BIM is to shift your efforts to the pre-construction phase. Many contractors make the mistake of starting coordination only after mobilization. This reactive approach often leads to a scramble for information when crews are already waiting for instructions.

Start the coordination process during the design development or early bid phase. By virtually constructing the building before a single shovel hits the dirt, you identify major spatial constraints immediately. This early involvement allows the team to rerouting major runs or adjust structural elements while they exist only as digital pixels, rather than concrete and steel.

Automate Clash Detection Protocols

Visual inspection of a 3D model is helpful, but it is not foolproof. To truly integrate BIM, contractors must use automated clash detection software. Tools like Navisworks or Solibri allow you to run interference checks between different trade models.

You should establish a routine for these checks. For example, run clash reports weekly and categorize them by severity. Focus first on hard clashes, such as a plumbing pipe running through an HVAC duct. Investing in professional MEP Coordination Services helps identify these hard clashes early, ensuring that the field team receives a conflict-free installation plan. By automating this process, you remove human error and ensure that every inch of ceiling space is accounted for.

Establish a Robust BIM Execution Plan (BEP)

Technology fails without a roadmap. A BIM Execution Plan (BEP) is a critical document that defines how the modeling process will work. For a contractor, the BEP is not just paperwork; it is the rulebook for the project.

Your BEP should clearly define:

- Level of Development (LOD): How detailed does the plumbing model need to be? Does it need hangers and insulation, or just the pipe geometry?

- Coordinate Systems: Ensure all trades are modeling in the exact same virtual space.

- File Exchange Formats: Decide on software versions and file types (e.g., IFC, RVT, NWD).

When everyone follows the same BEP, the integration of different trade models becomes seamless. It prevents the frustration of receiving a file that doesn’t line up with the architectural grid.

Leverage BIM for Prefabrication and Modular Construction

One of the most powerful ways to integrate BIM is to use it as a driver for off-site prefabrication. When your model is accurate, you don’t need to measure and cut in the field. You can spool drawings directly from the model and fabricate complex assemblies in a controlled shop environment.

This is where precise Mechanical BIM services shine. By modeling ductwork and piping to fabrication-level detail, contractors can build multi-trade racks or bathroom pods off-site. These units are then trucked to the site and lifted into place. This strategy significantly reduces waste, improves safety by limiting ladder time, and accelerates the installation schedule.

Adopt Cloud-Based Collaboration Platforms

Siloed information is the enemy of efficiency. If the mechanical subcontractor is working on a local file that is three days older than the electrical subcontractor’s file, clashes are inevitable. Integrating cloud-based platforms like Autodesk Construction Cloud or Procore creates a “Common Data Environment” (CDE).

A CDE ensures that everyone is looking at the single source of truth. When a change is made to the architectural model, all trades see it instantly. This real-time collaboration allows for faster decision-making. If an RFI (Request for Information) is generated, it can be linked directly to the specific location in the 3D model, giving the design team immediate context and speeding up the approval process.

Utilize 4D BIM for Scheduling Logistics

Time is a physical constraint on a job site, just like a concrete wall. 4D BIM integrates the project schedule with the 3D model. This allows contractors to visualize the sequence of construction over time.

By linking the model elements to the timeline, you can spot logistical issues that a Gantt chart might hide. For instance, you might see that the mechanical crew is scheduled to install overhead ductwork in a corridor at the same time the flooring crew is pouring concrete below them. 4D simulation highlights these trade stacking issues, allowing you to adjust the schedule before crews arrive. This visualization ensures a smoother flow of work and prevents trades from tripping over one another.

Enhance Cost Estimation with 5D BIM

Contractors can integrate BIM into their financial workflows by using the model for quantity take-offs. This is often called 5D BIM. Instead of manually counting fixtures or measuring linear feet of pipe from 2D PDFs, the model can generate exact material quantities instantly.

This integration allows for more accurate bidding and procurement. When design changes occur, the cost implications update automatically based on the new quantities. Accurate Mechanical BIM services ensure that every valve, elbow, and transition is accounted for, reducing the risk of material shortages or expensive over-ordering. This level of precision protects the project budget and helps maintain healthy cash flow.

Validate Installation with Reality Capture

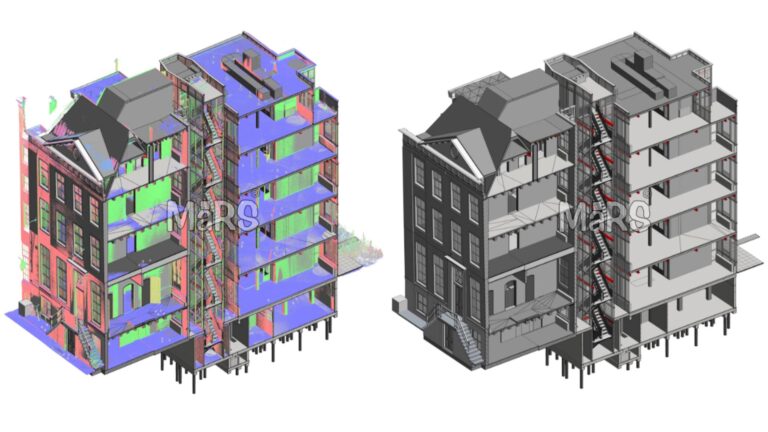

The integration of BIM shouldn’t stop once installation begins. Contractors are increasingly using laser scanning and reality capture technology to validate that the field work matches the coordination model.

By scanning the site at key milestones—such as before wall closure—you can overlay the as-built point cloud onto the as-designed model. This quality control step verifies that pipes and conduits are exactly where they are supposed to be. If a deviation is found, it can be corrected immediately rather than discovered later during commissioning. This creates a digital twin of the facility, providing immense value for future maintenance and operations.

Conclusion

Integrating BIM coordination is no longer an optional upgrade for modern contractors; it is a necessity for staying competitive. It moves the construction industry away from uncertain estimates and field conflicts toward precision and predictability.

From early pre-construction planning to the final reality capture scan, these eight strategies provide a framework for success. By fully embracing MEP Coordination Services, contractors safeguard their bottom line, improve relationships with trade partners, and deliver higher-quality buildings. The transition requires commitment and the right tools, but the return on investment—measured in time saved and errors avoided—is undeniable.