Modern construction projects face increasing complexity due to renovations, retrofits, and expansions of existing buildings. Original drawings often fail to reflect modifications made over time, such as concealed MEP reroutes, structural reinforcements, or minor architectural changes. Even small discrepancies between design documents and actual site conditions can lead to costly rework, project delays, and resource misallocation. Accurate As-Built BIM data captures these nuances, allowing teams to detect potential clashes, plan installations precisely, and reduce errors that typically arise from assumptions. With highly detailed models, designers and engineers gain a reliable digital representation of the building. Which improves coordination across disciplines and supports better-informed decisions throughout the project lifecycle.

As-Built Modeling Services take this process further by combining advanced laser scanning, point cloud processing, and Revit modeling to create verified, data-driven BIM models. These services transform raw site measurements into accurate 3D models that preserve real-world geometry and system layouts. Construction teams can identify hidden structural elements, evaluate spatial constraints, and plan phased renovations effectively. Facility managers benefit from precise asset documentation, while architects and engineers use the models to confidently update designs. Stakeholders reduce errors, avoid costly surprises, and establish a trustworthy reference for both construction and long-term building operations.

Why As-Built BIM Data Accuracy Remains a Major Industry Challenge?

Many existing buildings lack reliable records of past modifications, undocumented retrofits, or structural changes. Original drawings often omit minor adjustments made during construction, such as relocated ducts, hidden piping, or wall thickness changes. Renovation teams frequently rely on assumptions or visual inspections to fill these gaps, which increases the risk of errors in design and construction. Additionally, complex MEP networks, multi-level structures, and aging facilities make manual measurement difficult and prone to inconsistencies. These factors make it challenging to create a fully accurate as-built digital model using traditional methods, leaving teams vulnerable to coordination issues and costly delays.

Another challenge arises from the diversity of stakeholders involved in building projects. Architects, structural engineers, MEP designers, and contractors often work with different data sources that vary in quality and detail. Discrepancies between these sources cause misalignment in project models and reduce confidence in BIM outputs. Even small inaccuracies in spatial dimensions or system layouts can lead to clashes, rework, and increased project costs. Without standardized workflows or advanced validation processes, maintaining high-quality As-Built BIM data remains a persistent industry problem that affects project efficiency, safety, and long-term facility management.

How Inaccurate As-Built Data Affects Design, Cost, and Construction?

Inaccurate data can have cascading effects across design, cost, and construction. Designers may create plans based on incorrect dimensions, resulting in frequent revisions and redesign efforts. Structural elements or MEP systems installed in unrecorded locations can conflict with new installations, triggering on-site clashes that halt progress. Contractors face unexpected adjustments, leading to increased labor hours and material waste. Budget estimates often fail when unforeseen conditions emerge, causing cost overruns and financial strain. Project schedules also suffer as teams pause work to resolve conflicts or validate measurements. Even minor deviations, such as misaligned walls or concealed ductwork, can propagate errors throughout a project, reducing efficiency and increasing risk. Accurate, verified data is essential to prevent these issues, allowing teams to plan construction sequences effectively, optimize resource allocation, and maintain both quality and timeline commitments.

Why Traditional As-Built Documentation Cannot Support Modern BIM?

Traditional as-built documentation struggles to meet the demands of modern BIM workflows due to its limited accuracy, inconsistent detail, and lack of digital integration. Paper drawings or manual measurements often miss subtle site changes, creating gaps that affect model reliability. Unlike BIM-ready data, these methods cannot capture complex geometries or hidden systems efficiently.

Key limitations include

- Inability to represent three-dimensional spatial relationships accurately

- Difficulty in updating documents after modifications

- Lack of standardized data for multi-disciplinary collaboration

- Challenges in integrating with software like Revit or Navisworks

What Scan to Revit Services Deliver?

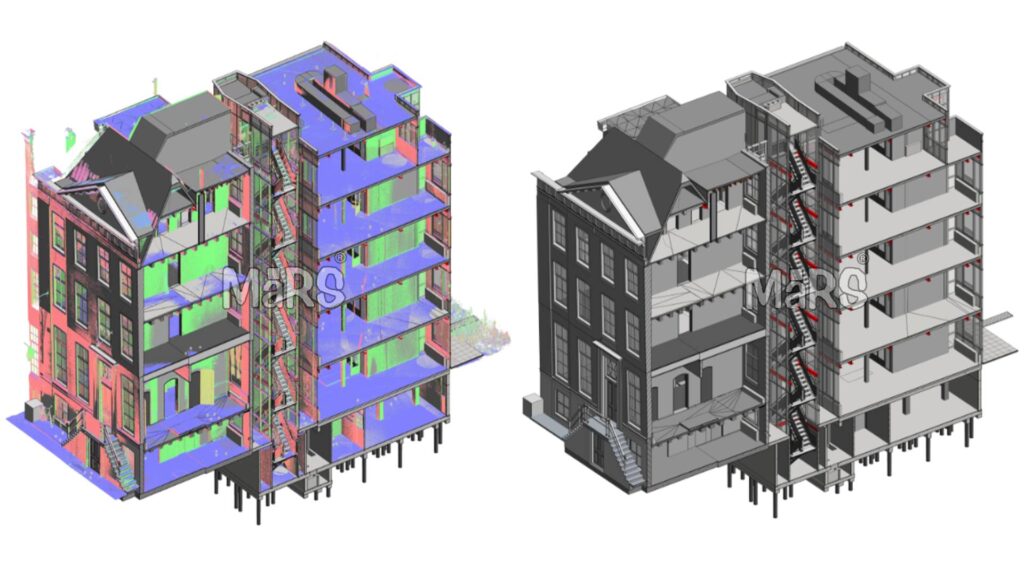

Point cloud to Revit services capture real-world conditions using high-precision laser scanning and convert them into structured BIM models. They provide accurate geometry, dimensions, and system layouts, reflecting the true state of a building. By integrating this data into Revit, teams can generate coordinated, discipline-specific models for architecture, structure, and MEP. These services improve design validation, clash detection, and project planning, giving stakeholders a reliable digital twin that supports renovations, retrofits, and facility management with verified as-built information.

How the Workflow Produces Reliable As-Built Data?

Laser Scanning for Existing Condition Capture

Laser scanners capture millimeter-accurate measurements of building elements, including hidden MEP ducts, ceiling voids, and structural reinforcements, creating high-density point clouds that reflect actual site conditions.

Point Cloud Processing for Data Accuracy

Point clouds undergo registration and alignment checks; noise from reflective surfaces or furniture is removed, and overlapping scans are merged to produce a clean dataset ready for precise modeling.

Point Cloud-Based Modeling in Revit

Using scan data as reference, Revit modeling extracts geometry of walls, columns, beams, and mechanical systems with exact coordinates, maintaining scale accuracy for clash detection and design validation.

Development of Discipline-Specific As-Built Models

Separate models for architecture, structure, and MEP are created at LOD 300–400, capturing hidden elements and real-world deviations, which allows coordination, phased construction planning, and accurate documentation for contractors.

How It Solves Common As-Built Modeling Problems?

Scan to Revit eliminates errors caused by manual measurements by capturing precise dimensions and alignment of structural, architectural, and MEP elements. It documents concealed areas like ceiling voids, ductwork, and underground piping that traditional methods miss. Complex geometries, such as curved walls or irregular facades, are accurately represented in Revit models. By providing a single, verified source of as-built data, 3D scan to BIM reduces on-site conflicts, improves coordination among disciplines, and delivers reliable BIM models ready for design, renovation, or facility management.

Long-Term BIM Value Across Projects and Asset Lifecycles

Revit Is Essential for Converting Scan Data into BIM Assets

Revit transforms scan data into parametric BIM elements, enables clash detection using real site conditions, and integrates As-Built models with drawings, schedules, and documentation for accurate design and project execution.

Scan to Revit Services Improve Multidisciplinary Coordination

A single source of verified As-Built BIM data allows architectural, structural, and MEP teams to align models effectively, reducing coordination conflicts and supporting consistent updates throughout design and construction phases.

Renovation and Retrofit Projects Depend on Scan to Revit

Scan to Revit identifies undocumented building changes, supports phased construction planning, and minimizes on-site modifications, ensuring accurate execution for renovation, retrofit, or adaptive reuse projects.

Facility Management Requires Scan to Revit As-Built Models

BIM-based as-built models help track assets, plan spaces with verified dimensions, and provide long-term operational reference for maintenance teams and facility managers.

Quality Control Defines Successful Scan to Revit Projects

Verifying Revit models against point cloud data, performing tolerance checks, and following consistent modeling standards ensures high-quality, accurate, and reliable As-Built BIM deliverables.

What Happens When Scan to Revit Is Ignored in As-Built BIM?

When teams skip service they produce inaccurate As-Built models that trigger design mistakes and require frequent rework. Contractors encounter on-site conflicts from missing or incorrect spatial and system data. Architects and engineers struggle to coordinate disciplines, causing delays and inefficiencies. Renovation and retrofit plans suffer from undocumented changes, forcing teams to make assumptions during execution. Facility managers receive unreliable BIM data, which limits asset tracking and space planning. Ignoring Scan to Revit directly reduces project accuracy, workflow efficiency, and long-term BIM value.

Conclusion

Scan to Revit services transform how project teams handle As-Built BIM data by directly linking field reality with digital models. Teams capture complex geometries, concealed systems, and undocumented site changes with precision. Revit-based workflows convert this data into coordinated, discipline-specific BIM models that support design decisions, clash detection, and phased construction planning. Renovation and facility management teams gain verified information for asset tracking and space optimization. By embedding accuracy and validation at every stage, It reduces rework, accelerates project delivery, and secures the long-term value of BIM across the asset lifecycle.