ESD Flooring – What it is

Electrostatic discharge (ESD) is a sudden flow of electricity between two electrically charged objects, which can cause significant damage to electronic components. ESD flooring is designed to prevent this by providing a conductive path for static electricity to dissipate safely. Historically, electrostatic discharge has been a concern since the early days of electronics, with solutions evolving from basic grounding techniques to advanced flooring systems. Click here to know more.

An estimated $5 billion in annual losses are incurred by the global electronics industry due to electrostatic discharge (ESD) damage. The necessity for effective electrostatic discharge protection, such as ESD flooring, is marked by these losses. Immediate damage to electronic devices is caused by ESD events, leading to costly repairs and downtime. Risks are mitigated by electrostatic discharge flooring, which safely dissipates static electricity, reducing failures and associated expenses. (Wootc, 2023)

The following is a summary representation of the ESD damage global statistic:

ESD flooring plays a crucial role in safeguarding sensitive electronic equipment by providing a conductive path for static electricity to dissipate safely.

Understanding ESD and Its Impact

Electrostatic discharge (ESD) occurs through various mechanisms, impacting sensitive electronic components:

- Triboelectric Effect: ESD is caused by electron transfer when two materials make contact and separate, creating an imbalance of charge.

- Electrostatic Induction: A charge is induced in a conductive object when exposed to a charged object while being isolated from the ground.

- Corona Discharge: A strong electric field around a conductor ionizes nearby air, resulting in continuous discharge.

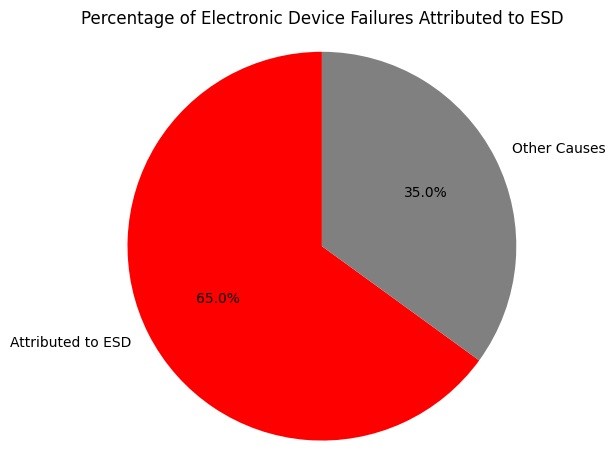

Percentage of Electronic Device Failures Attributed to ESD

It has been estimated that approximately 60-70% of all electronic device failures can be attributed to electrostatic discharge (ESD). This significant percentage underscores the critical impact of ESD on the reliability and durability of electronic components. ESD events can cause immediate and often irreversible damage to sensitive electronics, leading to substantial financial losses and operational disruptions. Implementing effective electrostatic discharge protection measures, such as electrostatic discharge flooring, is essential to mitigate these risks. By providing a controlled path for static electricity to dissipate safely, ESD flooring helps reduce the incidence of electrostatic discharge-related failures, thereby enhancing the overall reliability of electronic devices as displayed on the chart below.

The Role of ESD Flooring

ESD flooring materials are specifically engineered to regulate electrical resistance, preventing the buildup and uncontrolled discharge of static electricity. These flooring solutions play a vital role in safeguarding sensitive electronic components and maintaining safety in environments prone to electrostatic issues.

- Carbon-Loaded Vinyl: Durable and highly efficient at dissipating static electricity, ideal for high-traffic areas

- Static-Dissipative Epoxy: Provides a seamless, chemical-resistant surface suitable for cleanrooms and manufacturing facilities

According to Static Worx, flooring materials are categorized by electrical resistivity. Materials with resistivity ≤1.0 x 10^6 ohms are classified as conductive and enable static electricity to dissipate directly, including carbon-loaded vinyl. Materials with resistivity between 1.0 x 10^6 and 1.0 x 10^9 ohms are categorized as static-dissipative, such as static-dissipative epoxy, which allows controlled dissipation of static electricity. Proper understanding of these categories ensures optimal ESD flooring solutions for industrial protection.

Industries Benefiting from ESD Flooring

ESD flooring has proven essential in several industries by protecting sensitive equipment from electrostatic damage:

- Aerospace: Safeguards avionics and critical electronic systems, ensuring operational reliability and safety in aircraft.

- Automotive: Enhances the durability of electronic control units (ECUs) and sensors, crucial for vehicle performance and safety.

- Semiconductor Manufacturing: Prevents damage to microchips and other high-value components, reducing production losses and maintaining quality standards. These benefits highlight ESD flooring’s role in supporting advanced technological industries.

According to In Compliance Magazine, statistics show that Companies using ESD flooring have reported up to a 10.73% increase in product yield and significant reductions in repair costs as seen in the figure below;

Companies that have implemented ESD flooring have reported up to a 10.73% increase in product yield. This improvement is attributed to the effective prevention of electrostatic discharge (ESD) damage, which can otherwise lead to costly repairs and production downtime. Additionally, significant reductions in repair costs have been observed, further highlighting the financial benefits of ESD flooring. By providing a controlled path for static electricity to dissipate, electrostatic discharge flooring enhances the reliability and longevity of electronic components, ultimately contributing to better overall operational efficiency. (Compliance, 2014)

The Future of ESD Flooring

Emerging technologies in ESD flooring include smart systems with integrated sensors and monitoring capabilities. These systems can provide real-time data on static levels and floor performance, enhancing safety and efficiency, turning the future of ESD flooring market positive with a non-stopping growth expected by the key industries. Meet the experts that have played a pivotal role in developing the manufacturing, supplying and installation of the electrostatic discharge flooring.

According to Dataintelo, the global ESD flooring market is projected to grow from $5.2 billion in 2023 to $8.9 billion by 2032, at a CAGR of 6.2%. The growth of the market is being driven by increasing demand for ESD flooring in industries where static electricity endangers sensitive electronics and human safety. Technological advancements in flooring materials and rising awareness of ESD control’s significance in manufacturing environments are contributing to the market’s expansion and adoption of these solutions. (Dataintelo & Sharma, 2019).

References

- Compliance, I. (2014, June). The “Real” Cost of ESD Damage – In Compliance Magazine. In Compliance Magazine. https://incompliancemag.com/the-real-cost-of-esd-damage/

- Dataintelo, & Sharma, R. (2019, November 4). ESD Floor Market Research Report 2032. Dataintelo.com. https://dataintelo.com/report/esd-floor-market

- What is Electrical Resistance? | Learning Center | StaticWorx. (2023, August 18). StaticWorx GroundSafe . https://staticworx.com/learning_center/esd-flooring-technical-information/electrical-resistance/

- wootc. (2023, April 23). Electrostatic Discharge Sensitive Components: Grading, Damage Cases, and Industry Statistics – wootC ESD & Anti-static. Wootc.com. https://www.wootc.com/knowledge-base/electrostatic-discharge-sensitive-components-grading-damage-cases-and-industry-statistics.html