In today’s fast-paced industrial environment, companies are always looking for ways to improve efficiency and reduce costs. One area where significant advancements have been made is in pumping solutions. Automated industrial pumping solutions are becoming increasingly popular, and for good reason. In this article, we will explore the benefits of using automated pumping systems and how they can transform your operations.

Understanding Automated Industrial Pumping Solutions

What Are Automated Industrial Pumping Solutions?

Automated industrial pumping solutions are systems designed to move fluids in various industrial processes without requiring constant manual intervention. These systems can be programmed to operate on a schedule or based on specific conditions, allowing for greater control and efficiency. They often include sensors, controllers, and software that work together to monitor and manage fluid movement.

Note: For efficient and reliable operations, businesses often seek expert providers of industrial pumping solutions. These services are essential for transporting fluids in various industries, ensuring smooth workflows and minimal downtime. From water management to oil and gas applications, having the right pumping solutions is crucial. For top-notch services tailored to your needs, reach out to Forte Oil Field Services today and discover how they can enhance your operations!

How Do They Work?

Automated pumping systems use various technologies to ensure fluid is pumped accurately and efficiently. Here are some of the key components involved:

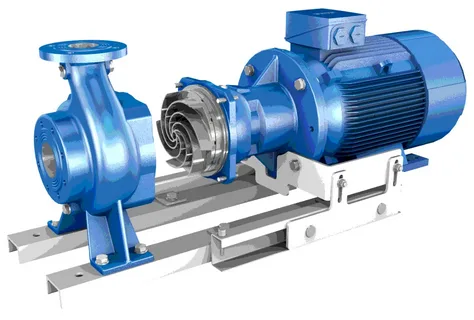

- Pumps: These are the heart of the system. They come in various types, including centrifugal pumps and positive displacement pumps, depending on the fluid being moved.

- Sensors: These devices monitor various parameters such as pressure, flow rate, and temperature. They provide real-time data to the control system.

- Control Systems: This includes software and hardware that process data from the sensors and make decisions about when to pump, how fast, and for how long.

- Communication Interfaces: These allow the system to communicate with other machinery or central control systems for better coordination.

Benefits of Using Automated Industrial Pumping Solutions

Automated industrial pumping solutions offer numerous advantages that can significantly improve your operations. Let’s take a closer look at these benefits.

Improved Efficiency

Optimized Fluid Movement

Automated systems can optimize the movement of fluids through pipelines and equipment. They can adjust pumping rates based on real-time data, ensuring that the right amount of fluid is delivered exactly when needed. This eliminates waste and keeps processes running smoothly.

Reduced Downtime

With automation, pumps can operate continuously and efficiently, minimizing the chances of breakdowns. Regular maintenance can be scheduled automatically, which helps keep everything running at peak performance. This means less downtime for repairs and more productive time for your operations.

Cost Savings

Lower Labor Costs

One of the most significant financial benefits of automated pumping solutions is the reduction in labor costs. With fewer employees needed to monitor and manage pumping operations, companies can allocate resources more effectively. This not only saves money but also allows staff to focus on more strategic tasks.

Decreased Energy Consumption

Automated systems can be programmed to operate during off-peak energy hours or adjust their operation based on demand. This leads to significant energy savings, which can greatly reduce operating costs. Energy-efficient pumps are designed to use less power while still providing the necessary flow rates.

Enhanced Accuracy and Precision

Consistent Flow Rates

Automated pumping systems provide precise control over flow rates. This ensures that the right amount of fluid is delivered consistently, which is crucial in many industrial processes. This accuracy helps to maintain product quality and reduces the risk of errors that can lead to costly rework or waste.

Real-Time Monitoring

With sensors and monitoring systems in place, automated pumps can detect any irregularities in performance. If something goes wrong, the system can alert operators immediately, allowing for quick action to be taken. This real-time monitoring helps to maintain high standards of quality and safety.

Increased Safety

Reduced Human Error

Automating pumping operations reduces the reliance on human intervention, which is often a source of mistakes. With automation, the potential for errors is minimized, leading to a safer working environment. This is particularly important in industries where handling hazardous materials is involved.

Enhanced Emergency Response

Automated systems can be programmed to respond to emergencies automatically. For instance, if a leak is detected, the system can shut down the pump and alert operators immediately. This quick response can prevent accidents and minimize damage.

Greater Flexibility

Adaptability to Changing Needs

Automated pumping solutions can easily adapt to changing production demands. If a company needs to increase or decrease the flow of a fluid, the system can be reprogrammed quickly. This flexibility is essential for businesses that need to respond to market changes rapidly.

Integration with Other Systems

Automated pumps can be integrated with other machinery and systems within the facility. This allows for a seamless flow of information and helps optimize overall operations. For example, an automated pump can work in conjunction with a filtration system to ensure that the right amount of fluid is being treated at all times.

Better Data Collection and Analysis

Enhanced Performance Tracking

Automated systems collect data continuously, providing valuable insights into the performance of pumping operations. This data can be analyzed to identify trends, track efficiency, and pinpoint areas for improvement. By leveraging this information, companies can make informed decisions to optimize their processes further.

Predictive Maintenance

With the data collected from automated systems, companies can implement predictive maintenance strategies. This means they can analyze trends and forecast when maintenance is needed, rather than waiting for a failure to occur. This proactive approach can save time and money while improving overall reliability.

Conclusion: Embracing the Future of Pumping Solutions

In summary, automated industrial pumping solutions offer a wide range of benefits that can enhance efficiency, reduce costs, and improve safety in various industrial applications. By integrating automation into pumping operations, companies can optimize their processes, ensure consistent quality, and adapt to changing demands.

As industries continue to evolve, embracing automation will be key to staying competitive. Whether you’re in manufacturing, chemical processing, or another sector, investing in automated pumping solutions can help you achieve your operational goals.

If you’re considering upgrading your pumping systems, now is the time to explore automated options. The benefits are clear, and the potential for improvement is significant. Take the first step toward a more efficient and cost-effective future with automated industrial pumping solutions.

For More Insightful Articles Related To This Topic, Feel Free To Visit: kataberita.