Pipe integrity is a fundamental aspect of maintaining the safety and efficiency of industrial operations, especially in sectors like oil and gas, power generation, chemical processing, and marine. Over time, pipes can experience wear and degradation from factors such as corrosion, erosion, and fatigue. This can result in thinning of the pipe walls, compromising their structural integrity. To detect thinning before it leads to catastrophic failure, regular pipe thickness measurement is critical. Ultrasonic pipe thickness measuring instruments have become the preferred choice for this task, offering a fast, non-destructive, and highly accurate way to measure metal thickness.

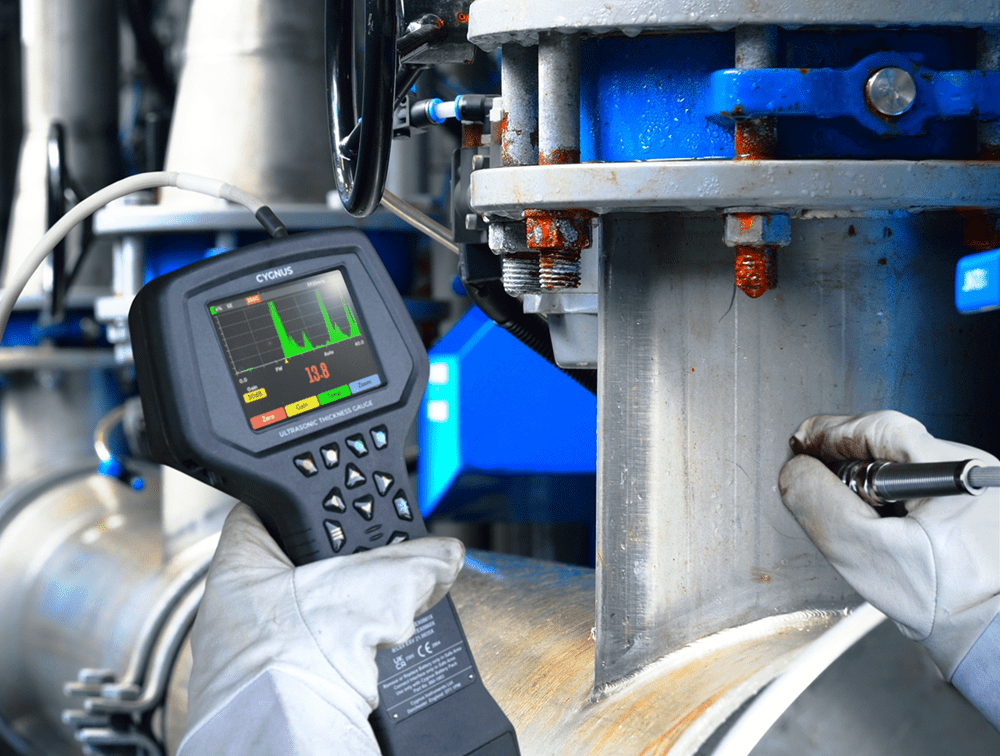

Cygnus Instruments has established itself as a leader in the design and manufacture of ultrasonic thickness gauges. With a strong focus on precision, durability, and user-friendly design, Cygnus has earned the trust of industries worldwide. In this article, we will explore the importance of pipe thickness measurement, how ultrasonic thickness gauges work, and why Cygnus Instruments is the top choice for reliable pipe thickness measuring instruments.

The Importance of Measuring Pipe Thickness

Pipes are crucial in many industrial operations, transporting fluids, gases, and chemicals. Over time, pipes can degrade due to several factors:

- Corrosion: The chemical reaction between the pipe material and the transported substance, or the external environment, can lead to rust and thinning.

- Erosion: The flow of abrasive materials through the pipe can gradually wear down the walls.

- Fatigue: Continuous stress and pressure fluctuations can cause pipe walls to thin or crack.

If these issues go undetected, they can lead to significant safety hazards, including leaks, ruptures, and even environmental disasters. Measuring pipe thickness regularly helps to monitor the condition of the pipes, enabling early detection of thinning and preventing serious problems. Accurate pipe thickness measurement also allows operators to:

- Plan preventive maintenance: Identify areas that require attention before they fail.

- Extend the lifespan of assets: Reduce the need for expensive replacements by addressing issues early.

- Ensure safety: Avoid catastrophic accidents and leaks by proactively monitoring pipe integrity.

- Comply with regulations: Meet industry standards for regular inspection and maintenance of critical infrastructure.

How Ultrasonic Thickness Gauges Work

Ultrasonic thickness measuring instruments use the principle of sound wave transmission to measure the thickness of materials. These gauges emit high-frequency sound waves through the material being tested. The sound waves then travel through the pipe until they encounter the far side. Once the waves hit the opposite surface, they reflect back to the transducer. By measuring the time it takes for the sound waves to travel to the opposite side and return, the ultrasonic gauge can calculate the thickness of the material.

The process is non-destructive, meaning the pipe doesn’t need to be cut or altered in any way. Ultrasonic thickness gauges are ideal for measuring the thickness of materials in service, including pipes that are coated, corroded, or otherwise damaged.

Advantages of Using Ultrasonic Pipe Thickness Measuring Instruments

There are several reasons why ultrasonic thickness gauges are the preferred choice for measuring pipe thickness:

- Non-destructive testing: Ultrasonic testing doesn’t cause any damage to the pipe, making it ideal for regular inspections of operational pipes.

- Accuracy: These gauges offer high precision, providing reliable readings even on pipes with coatings, rust, or other surface irregularities.

- Speed: Ultrasonic gauges deliver instant results, helping operators quickly assess the condition of pipes without the need for extensive downtime or deconstruction.

- Versatility: Ultrasonic thickness gauges can measure the thickness of various materials, including metals, plastics, and composites, making them suitable for a wide range of industrial applications.

- Cost-effectiveness: Since ultrasonic testing doesn’t require pipe disruption or costly disassembly, it’s a more economical method for ongoing pipe inspections.

Why Cygnus Instruments Stands Out

Cygnus Instruments is recognised globally as a leading provider of high-quality pipe thickness measuring instruments. The company has developed a strong reputation for its commitment to precision, innovation, and customer satisfaction. Here’s why Cygnus Instruments is trusted by industries worldwide:

1. High Accuracy and Precision

Cygnus ultrasonic thickness gauges are renowned for their exceptional accuracy. In critical industries where precision is essential, Cygnus instruments deliver consistent, reliable measurements. This allows operators to make informed decisions about when and where maintenance is needed, preventing costly downtime and reducing the risk of accidents.

2. Rugged, Durable Design

Industrial environments are often harsh, with pipes exposed to chemicals, extreme temperatures, high pressure, and vibration. Cygnus Instruments understands the challenges of these conditions and has designed their pipe thickness measuring instruments to be durable and reliable. Cygnus gauges are built to withstand these tough environments and continue to deliver accurate measurements even under demanding conditions.

Whether it’s offshore drilling platforms, chemical processing plants, or power stations, Cygnus gauges are engineered to endure and perform in the most challenging conditions.

3. Ease of Use

One of the standout features of Cygnus Instruments is the ease of use of their ultrasonic thickness gauges. The user-friendly design of their products makes it simple for operators, even those with minimal experience in ultrasonic testing, to take accurate readings quickly. With intuitive controls and clear, easy-to-read digital displays, Cygnus instruments streamline the inspection process, reducing the potential for operator error.

4. Versatility and Multi-Material Compatibility

Cygnus ultrasonic thickness gauges are highly versatile and capable of measuring the thickness of various materials, including metals like steel, aluminium, and copper, as well as non-metallic materials such as plastics and composites. This versatility ensures that Cygnus gauges can be used in a wide range of applications, from measuring the thickness of pipeline walls to inspecting tanks, hulls, and other structural components.

5. Data Logging and Reporting Features

Many of Cygnus’s ultrasonic gauges come with built-in data logging and reporting capabilities. This allows users to store measurements, track trends over time, and generate detailed reports. Data logging is particularly useful for businesses that need to maintain records for regulatory compliance or track the condition of pipes across multiple locations or inspection cycles.

6. Comprehensive Support and Training

Cygnus Instruments offers comprehensive customer support and training to help users get the most out of their equipment. Whether it’s through online resources, phone support, or hands-on training, Cygnus ensures that operators are well-equipped to use their pipe thickness measuring instruments effectively.

How to Measure Pipe Thickness with Cygnus Ultrasonic Gauges

Using Cygnus ultrasonic gauges to measure pipe thickness is straightforward and quick. Here’s a general guide:

- Surface Preparation: Clean the surface of the pipe to remove any dirt, grease, or corrosion that could interfere with the sound wave transmission. A clean surface ensures more accurate results.

- Calibrate the Gauge: Calibrate the ultrasonic thickness gauge using a reference block with a known thickness to ensure accuracy.

- Apply Coupling Gel: Apply a thin layer of coupling gel to the pipe surface. This gel ensures that the sound waves travel effectively between the transducer and the material.

- Take the Measurement: Place the transducer on the pipe’s surface and initiate the measurement. The ultrasonic gauge will calculate and display the pipe’s thickness.

- Repeat Measurements: Take multiple readings along the length of the pipe to identify any areas of thinning, corrosion, or wear.

- Store and Review Data: Save the measurements and store the data for later review. Many Cygnus gauges offer data logging features for easy tracking of pipe condition over time.

Applications of Cygnus Ultrasonic Thickness Gauges

Cygnus ultrasonic thickness gauges are used in various industries to ensure the integrity of pipes and critical infrastructure:

- Oil and Gas: Monitoring pipelines that transport oil and gas is essential to prevent leaks and ruptures. Cygnus gauges help detect corrosion or thinning in pipes, enabling proactive maintenance.

- Power Generation: In power plants, pipes carry steam and cooling water under high pressure and temperature. Regular thickness measurements help identify weak spots before they fail.

- Marine: Offshore platforms and ships are exposed to harsh marine environments. Cygnus ultrasonic gauges help monitor the condition of pipes, hulls, and other structural components for corrosion and thinning.

- Chemical Processing: Pipes in chemical plants are often exposed to corrosive substances. Cygnus gauges help detect thinning caused by corrosion and ensure the safe operation of these systems.

- Manufacturing: Regular inspection of pipes in manufacturing processes ensures smooth operations and reduces the risk of unexpected failures.

Conclusion

Accurate pipe thickness measurement is essential for maintaining the safety and efficiency of industrial operations. Ultrasonic pipe thickness measuring instruments, such as those offered by Cygnus Instruments, provide a reliable, non-destructive, and cost-effective solution for this task. With their precision, durability, and ease of use, Cygnus ultrasonic gauges have become the go-to choice for industries that rely on the integrity of their piping systems.

By investing in Cygnus pipe thickness measuring instruments, businesses can ensure the longevity and safety of their infrastructure, prevent unexpected failures, and stay compliant with industry regulations. Whether measuring metal thickness in pipelines, tanks, or structural components, Cygnus provides the tools necessary for effective pipe monitoring and maintenance.