Imidacloprid production cost analysis, examining how each factor plays a role in determining the overall expense of manufacturing this chemical. Imidacloprid is a widely used systemic insecticide belonging to the neonicotinoid class, effective against a broad range of pests in agriculture, horticulture, and household pest control. Its production cost is influenced by various factors, including raw material prices, energy consumption, labour, technological advancements, regulatory requirements, and economies of scale.

1. Raw Material Costs

The foundation of any chemical manufacturing process lies in its raw materials, and the production of Imidacloprid is no exception. The primary raw materials involved include:

- Chloropyridine: A key precursor in the synthesis of Imidacloprid. The price of chloropyridine fluctuates based on global production levels, availability, and feedstock costs, which can significantly impact the overall cost of production.

- Ammonium Acetate: Another essential ingredient for Imidacloprid production, its cost can vary depending on production levels and its demand in other chemical industries.

- Solvents and Reagents: Chemicals like dichloromethane and sodium hydroxide are necessary for the synthesis process, with their prices influenced by global supply and demand.

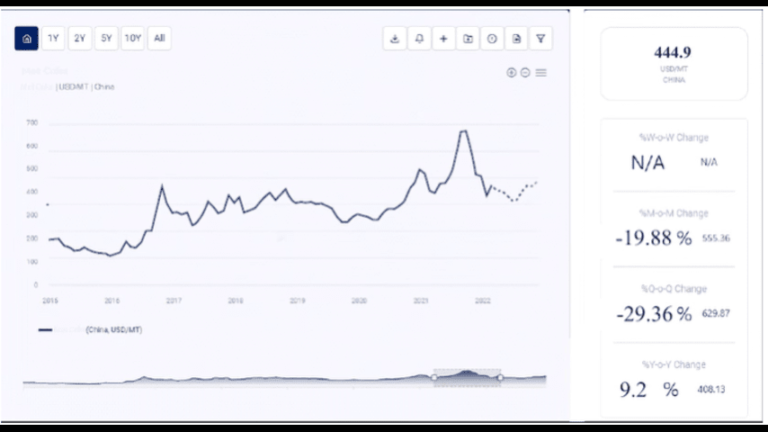

These raw material prices tend to fluctuate based on supply chain dynamics, including geopolitical factors, global demand, and disruptions in production, leading to variability in Imidacloprid’s production cost.

Request a Free Sample For Imidacloprid Production Cost Reports — https://www.procurementresource.com/production-cost-report-store/imidacloprid/request-sample

2. Energy Costs

The energy required for Imidacloprid production is a significant portion of the total production cost. The chemical process involves several stages, such as synthesis, purification, and drying, all of which are energy-intensive. Energy costs depend on:

- Energy Type: The choice of energy sources—whether natural gas, electricity, or renewable sources—affects the overall cost. Energy-intensive processes using fossil fuels tend to increase production costs in regions with high energy prices.

- Energy Efficiency: Companies that adopt energy-efficient technologies or renewable energy sources can reduce long-term costs. However, the initial investment in green technologies can be high.

The volatility in global energy prices, especially natural gas and electricity, directly impacts the cost structure of Imidacloprid production, making it one of the most dynamic components.

3. Labour and Operational Costs

Labour costs can vary significantly based on location, skill level required, and operational efficiency. Key factors include:

- Skilled Workforce: Imidacloprid production requires skilled chemists and technicians to ensure the chemical process runs smoothly and efficiently. Training and retaining a skilled workforce can be costly, particularly in regions with high labour wages.

- Operational Costs: The day-to-day operational costs, including facility maintenance, equipment upkeep, and administrative expenses, contribute to overall costs. Downtime, equipment failure, or inefficiencies can increase these costs.

Smaller manufacturers with limited labour resources may experience higher per-unit costs compared to larger firms with streamlined operations and economies of scale.

4. Technological and Innovation Costs

Technological advancements play a crucial role in improving the efficiency of Imidacloprid production. Companies that invest in research and development (R&D) to develop new, more efficient synthesis processes can reduce raw material and energy consumption, lowering overall production costs. Other technological considerations include:

- Automation: Implementing automated systems for manufacturing, quality control, and packaging can reduce human error and labour costs, leading to more consistent production at a lower per-unit cost.

- Process Optimisation: Continuous improvements in process efficiency, such as more effective catalysts or alternate chemical routes, can lead to lower costs over time, although these innovations typically require substantial initial investment.

While R&D and technology adoption may increase short-term expenses, in the long run, they can lead to significant cost savings.

5. Environmental and Regulatory Costs

Imidacloprid production is subject to stringent environmental regulations, particularly concerning waste management, emissions control, and chemical handling. Regulatory compliance adds to the cost of production, requiring investments in:

- Pollution Control: Equipment such as air filtration systems, wastewater treatment plants, and waste disposal processes are essential for complying with environmental standards, especially in regions with strict laws regarding chemical production.

- Sustainability Initiatives: As environmental concerns regarding pesticide use and chemical production increase, manufacturers are increasingly under pressure to adopt sustainable practices. This can include reducing the carbon footprint of production or exploring green chemistry alternatives, all of which come with associated costs.

Failure to comply with environmental regulations can lead to costly fines or the shutdown of production facilities, further underlining the importance of factoring these costs into the overall production budget.

Read Full Report — https://www.procurementresource.com/production-cost-report-store/imidacloprid

6. Economies of Scale

The scale of Imidacloprid production significantly impacts its cost structure. Large-scale producers can spread fixed costs, such as research, infrastructure, and equipment, over a greater volume of product, reducing the per-unit cost of manufacturing. On the other hand, smaller manufacturers may struggle to achieve these economies of scale, leading to higher per-unit costs.

Large chemical companies with efficient production plants often benefit from:

- Bulk Purchasing: They can secure raw materials in larger quantities, often at discounted rates, further reducing material costs.

- Streamlined Operations: Automation and process optimisation are easier to implement at larger scales, increasing overall production efficiency and lowering unit costs.

Smaller producers or those with limited production capacities may find it more difficult to compete with large-scale manufacturers, who can reduce costs through economies of scale.

7. Supply Chain and Distribution Costs

Supply chain costs, which include transportation, warehousing, and logistics, can also affect the production cost of Imidacloprid. These costs can fluctuate due to:

- Raw Material Sourcing: Raw materials often need to be transported over long distances, especially if they are sourced from different regions or countries. Transportation costs, which are influenced by fuel prices and geopolitical factors, can add to the overall production cost.

- Distribution Costs: Once the product is manufactured, distributing it to retailers, agricultural businesses, and other consumers also incurs costs. The need for extensive distribution networks, especially in remote regions, can further increase the cost.

Ask an Analyst – https://www.procurementresource.com/production-cost-report-store/imidacloprid/ask-an-analyst

Efficient logistics and supply chain management practices can help reduce these costs, ensuring that the price of Imidacloprid remains competitive in the market.

The production cost of Imidacloprid is determined by a variety of interconnected factors, each contributing to the overall expense. Raw material costs, energy consumption, technological innovation, labour costs, environmental regulations, and supply chain management all play crucial roles in shaping the final production cost. Understanding these factors helps manufacturers optimise production and develop cost-effective strategies.

For businesses involved in the production or procurement of Imidacloprid, staying informed about cost drivers and market trends is essential. By understanding the various elements that contribute to production costs, companies can make better decisions regarding sourcing, pricing, and investment in technology, ultimately improving their competitiveness in the global market.

Request a Free Sample — https://www.procurementresource.com/production-cost-report-store/imidacloprid/request-sample

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA