Introduction

Instant noodles, a popular convenience food around the globe, have become an essential part of modern living, especially for those seeking affordable and quick meals. The Instant Noodles Manufacturing Plant Project Report provides detailed insights into the feasibility and requirements of setting up a manufacturing plant for producing instant noodles. Instant noodles are often consumed due to their affordability, long shelf life, and ease of preparation. The growing demand for instant food, driven by busy lifestyles and the need for convenience, has made instant noodles one of the most widely consumed products in the world.

In this report, we will explore various aspects of establishing an instant noodles manufacturing plant, including market trends, production processes, equipment needed, investment analysis, and the regulatory framework involved in the operation of such a plant.

Market Demand and Growth of Instant Noodles

Global Demand for Instant Noodles

The global demand for instant noodles has been steadily increasing over the years. The growing working-class population, particularly in urban areas, has increased the consumption of ready-to-eat meals, including instant noodles. Furthermore, the affordability and quick preparation time of instant noodles make them an attractive option for college students, working professionals, and families.

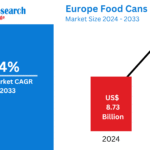

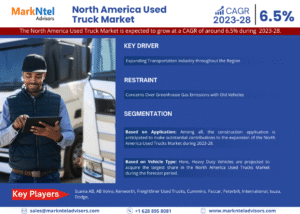

According to market research, the Asia-Pacific region remains the largest consumer of instant noodles, with countries like China, India, and Japan dominating the market. However, the demand for instant noodles is also expanding in other regions, such as North America, Europe, and Latin America, due to the growing popularity of Asian cuisine and the rising trend of convenient food products.

Factors Driving the Growth of Instant Noodles

- Urbanization: As more people migrate to urban areas for better job prospects, their time constraints increase, leading to a higher demand for convenient food products like instant noodles.

- Changing Lifestyles: In today’s fast-paced world, people often prefer meals that are quick to prepare. Instant noodles fulfill this need perfectly, offering a hassle-free meal solution for people with busy schedules.

- Affordability: Instant noodles are inexpensive compared to many other types of food. This makes them highly affordable and accessible for people across different income groups.

- Variety and Flavor Options: Instant noodles come in a wide range of flavors and types, allowing manufacturers to cater to diverse consumer preferences. Innovations such as vegan, gluten-free, or organic options are further driving the growth in the market.

- Long Shelf Life: Instant noodles have a long shelf life, making them an ideal product for both domestic and international markets. This feature also allows for cost-effective storage and distribution.

Get a Free Sample Report with Table of Contents@

Production Process of Instant Noodles

The manufacturing process of instant noodles involves several key steps to ensure the product’s quality, taste, and texture. These steps include dough preparation, steaming, frying (or non-frying), flavoring, and packaging.

Step 1: Preparation of Dough

The first step in the production process is preparing the dough. The main ingredients for making instant noodles are:

- Wheat flour: The primary raw material that forms the base of the noodles.

- Water: Used to knead the dough.

- Salt: Added to enhance flavor and texture.

- Alkaline salts: These are added to enhance the texture and color of the noodles. Common alkaline salts include potassium carbonate and sodium bicarbonate.

The ingredients are mixed in the required proportions to form a dough of the desired consistency.

Step 2: Rolling and Shaping the Dough

Once the dough is prepared, it is rolled out into thin sheets using rolling machines. These sheets are then passed through a cutter that shapes the dough into noodle strands. The thickness and width of the noodles can vary depending on the desired final product.

Step 3: Steaming (or Frying)

The next step is to cook the noodles. This can be done using two primary methods:

- Steaming: In this method, the shaped noodles are steamed for a short period to cook them. This is a healthier alternative to frying, as it preserves more nutrients.

- Frying: In this method, the noodles are deep-fried in hot oil. Frying gives the noodles their characteristic crispy texture and helps extend their shelf life.

Fried noodles are typically more common because they require less time to cook when rehydrated, and they have a longer shelf life compared to steamed noodles.

Step 4: Flavoring and Seasoning

Once the noodles are cooked, they are seasoned with various flavoring agents such as broth powders, spice mixes, or sauces. These flavoring agents are often packaged separately as seasoning packets for the consumer to add during preparation. The seasoning can include ingredients like soy sauce, curry powder, chicken or beef flavor, and dried vegetables.

For premium variants, manufacturers may add additional ingredients such as freeze-dried vegetables, flavor enhancers, and preservatives to enhance the taste and extend the shelf life of the noodles.

Step 5: Drying and Packaging

After the noodles are flavored, they undergo a drying process. This step helps remove excess moisture, ensuring that the noodles have a long shelf life. The drying process can be done in hot air ovens or through vacuum drying.

Once dried, the noodles are carefully packaged in airtight containers, usually plastic or foil packs, to prevent moisture absorption and ensure that the product stays fresh. The seasoning packets are also included in the packaging, ensuring the consumer can easily prepare the noodles.

Step 6: Quality Control

Throughout the production process, quality control is essential to ensure that the noodles meet the desired standards. The quality of the raw materials, the consistency of the dough, and the final texture of the noodles are all rigorously tested. Additionally, the flavor and seasoning levels are checked to ensure uniformity across batches.

Equipment Required for Instant Noodles Manufacturing Plant

Setting up an instant noodles manufacturing plant requires a range of specialized machinery and equipment for efficient production. Some of the key equipment needed includes:

- Flour Mixer: Used to mix wheat flour, water, and other ingredients to form the dough.

- Dough Sheeter: For rolling the dough into thin sheets.

- Noodle Cutter: Cuts the dough sheets into uniform noodle strands.

- Steaming or Frying Machines: Used to cook the noodles. These machines may either steam or fry the noodles, depending on the production method.

- Drying Ovens: Used to remove excess moisture from the noodles.

- Seasoning Machines: Used to apply flavoring to the noodles evenly.

- Packaging Machines: For sealing the noodles and seasoning packets in suitable packaging.

- Quality Control Equipment: Machines for testing texture, flavor, and consistency, ensuring that the final product meets industry standards.

Financial Investment and Business Considerations

Initial Investment

The initial investment required for setting up an instant noodles manufacturing plant includes several key expenses:

- Land and Infrastructure: The cost of land, building the production facility, and setting up the infrastructure.

- Machinery and Equipment: Investment in specialized machinery for each stage of production.

- Raw Materials: Procurement of wheat flour, seasonings, packaging materials, and other raw materials.

- Licensing and Permits: The necessary permits to operate a food manufacturing business, including safety and health certifications.

Operating Costs

Operating costs for an instant noodles manufacturing plant typically include:

- Labor: Salaries for workers, technicians, and administrative staff.

- Utilities: Costs for water, electricity, and gas for running machinery and ovens.

- Raw Materials: Continuous procurement of raw materials such as flour, seasonings, and packaging.

- Maintenance: Regular maintenance and repair of machines to keep production running smoothly.

Revenue Generation

Revenue is generated by selling instant noodles to retail markets, supermarkets, and wholesalers. Given the consistent demand for convenient food products, instant noodles can be sold at competitive prices, ensuring steady revenue for the business. Expanding the product range to cater to different consumer preferences, such as health-conscious variants, can further boost sales.

Regulatory and Certification Requirements

Setting up a manufacturing plant for food products requires adherence to strict safety, health, and quality standards. Some key regulatory requirements include:

- Food Safety Standards: Compliance with food safety regulations such as the Hazard Analysis and Critical Control Points (HACCP) to ensure that the product is safe for consumption.

- Health and Hygiene: Ensuring proper sanitation and hygiene practices throughout the production facility.

- Quality Certifications: Obtaining certifications such as ISO 9001 or other relevant quality management systems to ensure that the production meets industry standards.

- Environmental Regulations: Compliance with environmental laws to manage waste and emissions from the production facility.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au